India’s Growing Potential as the Next Semiconductor Hub

India is positioning itself as a major player in the global semiconductor industry. With rapid digitalization, increased demand for electronics, and a supportive government, the country aims to become a hub for semiconductor manufacturing and design.

While India has been traditionally known for its IT services and software development capabilities, its entrance into semiconductor manufacturing marks a significant shift towards hardware production and high-tech manufacturing.

Why India Has the Potential to Become a Semiconductor Hub

Several factors make India an attractive destination for semiconductor manufacturing:

1.Government Initiatives: The Indian government has launched several initiatives aimed at boosting semiconductor manufacturing. The Production Linked Incentive (PLI) scheme and Design Linked Incentive (DLI) schemes offer financial incentives for semiconductor companies to set up production and design units in India. Moreover, the government has allocated over $10 billion towards developing semiconductor and display manufacturing ecosystems.

2.Growing Market Demand: India’s domestic demand for electronics is skyrocketing. With over a billion smartphone users, rapid digital adoption, and increasing demand for devices like laptops, IoT products, and electric vehicles, India presents a huge market for semiconductors.

3.Skilled Workforce: India has a large pool of highly skilled engineers and technicians. Many global semiconductor companies have already set up design and R&D centers in India, leveraging the country’s strong talent in electronics design and software development.

4.Strategic Partnerships: India is working to strengthen partnerships with major semiconductor-producing countries like the U.S., Japan, and Taiwan. These partnerships aim to bring advanced semiconductor technologies to India and establish collaborative efforts in the semiconductor supply chain.

Major Semiconductor Companies Operating in India

Several global and Indian companies are already working in the semiconductor space in India, primarily in design, research, and recently, manufacturing.

1.Intel: Intel has a strong presence in India with its R&D facilities in Bengaluru. It has been working on cutting-edge chip design and software in India for many years.

2.Texas Instruments: One of the first companies to establish an R&D presence in India, Texas Instruments has been designing integrated circuits and chips in India for decades.

3.Qualcomm: Qualcomm operates significant research and development centers in India, focusing on mobile chipset design and 5G technologies.

4.Micron Technology: Micron has announced investments in India for chip design and development, including plans for a semiconductor testing and assembly plant.

5.STMicroelectronics: With a robust design and development center in India, STMicroelectronics has been working on automotive and industrial semiconductor solutions.

6.Tata Group: Tata has expressed its ambition to enter the semiconductor space, particularly through manufacturing partnerships and investments. It aims to build a comprehensive semiconductor ecosystem, ranging from chip manufacturing to packaging.

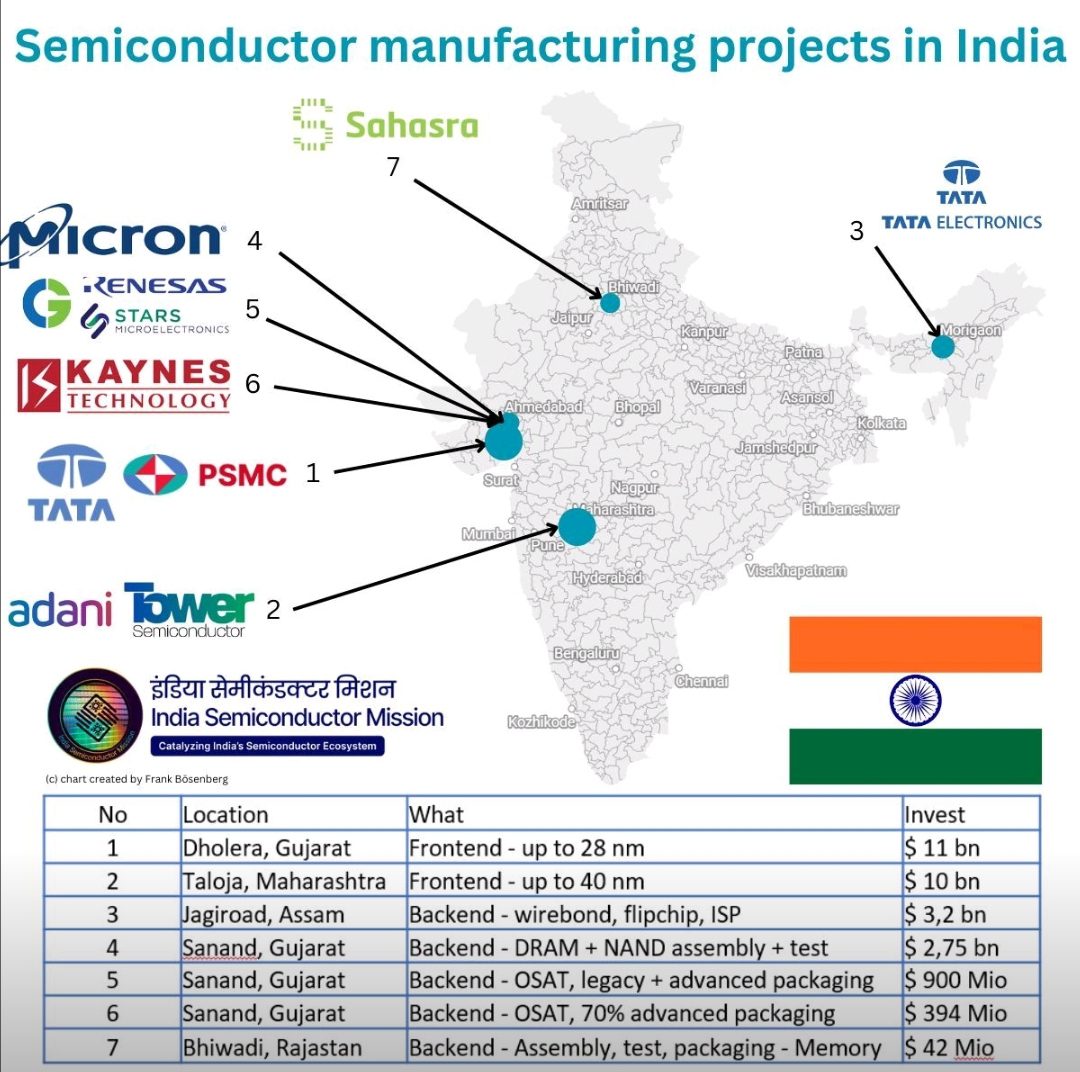

Key Semiconductor Manufacturing Projects in India

1.Vedanta-Foxconn Joint Venture: One of the largest semiconductor projects announced in India is the joint venture between Vedanta and Taiwan’s Foxconn. The collaboration, which aims to invest $19.5 billion, will establish a semiconductor and display fabrication plant in Gujarat. This is a significant step toward India’s goal of becoming self-reliant in semiconductor production.

2.ISMC Analog Fab Project: Another significant project is the proposed $3 billion semiconductor manufacturing plant in Karnataka by ISMC (a consortium of Abu Dhabi-based Next Orbit Ventures and Israeli tech company Tower Semiconductor). This facility will focus on producing 65nm analog chips, which are essential for automotive and industrial electronics.

3.Tata Electronics’ Chip Manufacturing: Tata Group is also making moves in semiconductor manufacturing. They have announced investments in establishing an OSAT (Outsourced Semiconductor Assembly and Testing) plant in Tamil Nadu. While the focus is currently on packaging and testing, Tata has long-term plans to set up a full-fledged semiconductor fabrication unit.

4.Applied Materials R&D Center: U.S.-based Applied Materials, a key player in semiconductor equipment manufacturing, has expanded its R&D capabilities in India. This center will work on advanced semiconductor materials and design, which will aid in the development of India’s semiconductor ecosystem.

5.Renewed Push for Fabless Design: India is also working to foster its local fabless semiconductor design ecosystem. Several start-ups in Bengaluru, Hyderabad, and Pune are working on chip design for applications ranging from IoT to automotive, powered by government incentives and industry collaborations.

Challenges and Opportunities

While the potential for India to emerge as a semiconductor hub is evident, several challenges remain:

–Capital-Intensive Nature: Semiconductor manufacturing is highly capital-intensive, requiring investments in billions. While India has the financial and human resources, attracting private investment and technology transfer will be key to building sustainable semiconductor fabs.

–Supply Chain: India currently lacks a robust semiconductor supply chain, especially in terms of raw materials and high-precision equipment. Building a reliable ecosystem will require collaborations with international players.

–Technological Expertise: Although India has excelled in chip design and R&D, semiconductor manufacturing requires deep expertise in fabrication technologies. Collaborations with established players from countries like Taiwan and the U.S. are essential to build the necessary capabilities.

Despite these challenges, the opportunities are immense. The global semiconductor shortage, geopolitical shifts, and India’s growing digital economy all create favorable conditions for the country to capitalize on.

Conclusion

India’s journey to becoming a global semiconductor hub is just beginning, but the progress made so far is promising. With strong government support, significant investments, and growing market demand, India could soon become a key player in the global semiconductor supply chain. Partnerships, technological advancements, and strategic planning will play a pivotal role in ensuring India’s success in this high-tech industry. The country’s ambition to be self-reliant in critical semiconductor technologies aligns with its broader vision of becoming a global manufacturing leader under initiatives like Make in India and Aatmanirbhar Bharat.